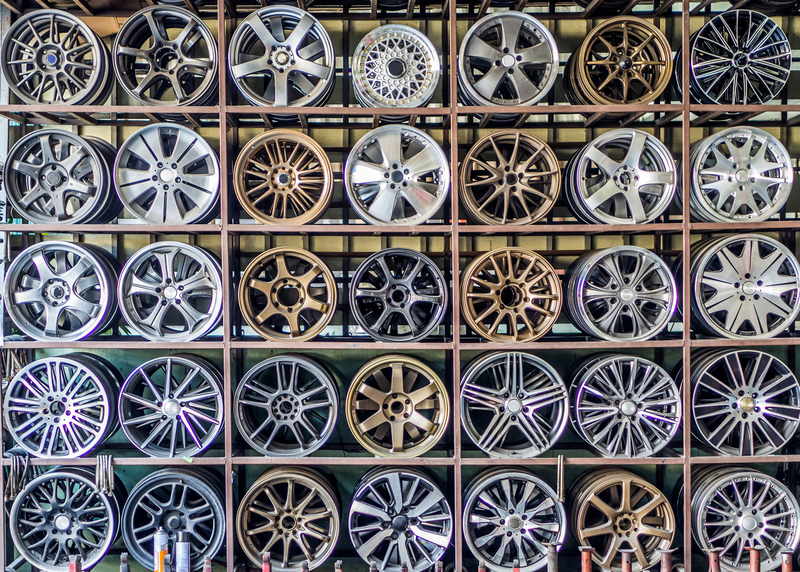

The experts at our car body shop know all about alloy wheel repair and alloy damage. The most common types are powder coated alloy wheels and diamond cut alloy wheels. If you find yourself requiring alloy wheel repair services, our car body shop specialists have revealed the differences between these types of wheels.

What are Diamond Cut Alloy Wheels?

This is an alloy wheel which has been put on a lathe and part of or the entire painted surface of the wheel machined off to leave a shiny alloy finish. A small part of the actual alloy is machined off to create this finish. It is then lacquered over to prevent corrosion. You will be able to see if your wheel is diamond cut if on close inspection you see very fine lines created by the cutting machine and the appearance is very shiny. This may be harder to distinguish if your wheels are of poor quality, old or corroded. Not all wheels can be diamond cut as this depends on the profile of the face of the wheel, but when doing alloy wheel repair, our car body shop can advise you on this. Our alloy wheel repair experts have found that diamond cut wheels will not retain their finish for as long as a powder coated wheel. Any damage to the lacquer however small will allow water to seep in-between the lacquer and the alloy leaving “milky patches” on the diamond cut finish area. Depending on the diamond cut alloy wheels, repair required is usually 1-2 cuts. If our car body shop finds that (when doing alloy wheel repair to your vehicle), the wheel will be compromised in any way and weakened, we will not cut the wheel and advise a powder coat finish for your refurbishment. Each wheel is assessed individually by our alloy wheel repair specialists. It is important to inform us if you know if your wheel has been cut before.

What are Powder Coated Alloy Wheels

Alloy wheel powder coating is sprayed on using a dry powder. The key difference between a diamond cut alloy wheel and a powder coated alloy wheel is that powder coating doesn’t need a solvent. The powder coating is applied electrostatically by using state-of-the-art powder coating equipment and cured using heat to allow it to create a durable layer. If you are considering getting your alloy wheels completely refurbished, a powder coating (rather than a traditional paint and lacquer approach) is one of the options available to you. There are a few different reasons why you might choose this finish. Alloy wheel powder coating is a decorative finish for alloy wheels. It’s sprayed on like traditional paint, however, it settles on the surface dry rather than liquid. It’s not until the coating is heated treated that the paint “flows out” of the coating and forms a gel over the surface of the wheel.

As with a standard re-spray, car bodywork repair or car scratch repair, alloy wheel powder coatings need to be lacquered over the top to protect against UV damage, light scratches, pollution and wash swirls. Many sources will inform you that alloy wheel powder coating provides a harder and more durable finish than a traditional paint re-spray. But equally, you might find powder coated rims accused of softening the underlying aluminum. It’s like most things in car repair, it all comes down to the quality of the finish. If the alloy wheels weren’t properly cleaned or heat-treated, to remove gases from the pores of the metal, you might find bubbles breaking the surface of the final paint job. Likewise, if the powder has not correctly flowed out to its gel form, or there has been no protective lacquer added over the top, you might find that it’s more susceptible to scratches and chips. It’s also possible to achieve more specialist finishes with powder coating. There’s some argument to say that powder finishes are better for the environment. This is because they don’t contain the same solvents as liquid paint and release fewer VOCs (volatile organic compounds) into the surroundings.

If you are looking to completely recolour your alloy wheels for cosmetic purposes, or the wheels have sustained substantial wear, tear or rust all over then powder coating your wheels might be a good choice. Wheels with structural damage should always be written off instead of repaired, for safety reasons.

Use Jenkins & Pain, Award-Winning Accident Repair Centre

There you have it, if you do find yourself with alloy damage and need a car repair or van repair you can count on us to complete all jobs using industry-standard processes. We offer free quotes and with our exclusive repair service, we are sure you will be happy with the results. Contact our Vehicle Body Shop today. Jenkins & Pain are a vehicle accident repair centre based in Dover, Kent. We are proud to call ourselves an award-winning accident repair centre. Check out our guide on how to look after your alloys! You can also paint your alloys to match your bodywork. Most popular car colours.

Ready to Visit Our Vehicle Body Shop?

We understand how costly and inconvenient it is for a vehicle to be off the road and therefore we use processes that ensure your vehicle is repaired quickly and efficiently. So whether you need minor scratch repairs, major body repair, or alloy wheel refurbishment, our van body shop and car body shop can guarantee a high-quality service. We also repair light commercial vehicles and motorhomes. Contact us today for a paint repair at our Car Body Shop!